Rapid Prototyping You can Choose

Rapid prototyping is a method of creating a physical prototype for something. In this blog article, we’ll discuss rapid prototyping and some of the services that can help you make your idea into reality!

The advantages of using RP over traditional manufacturing methods are clear:

- Traditional manufacturing processes can take weeks or even months to produce a final product, while RP can produce a physical prototype in days or hours.

- With RP, you can reduce the cost of your final product by eliminating the need for expensive tooling or production facilities.

- Because RP prototypes are created using digital models, they can be extensively tested before they are released to customers. This ensures that your product will meet expectations and meet regulatory requirements.

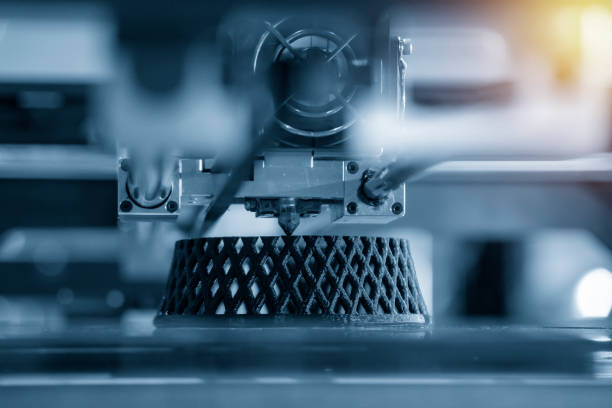

How does Rapid Prototype Work?

Rapid prototyping (RP) is the process of making a working model of a product or design as quickly as possible. This “fast-track” approach can save time and money while improving the quality of the end product.

There are several steps in RP, but the most important part is the design phase. You create a digital version of your product or design during this phase. This allows you to test different ideas and changes quickly and easily. Once you have a finalized design, you can start creating your prototype.

A prototype is a low-quality version of your final product. It’s designed to help you test different aspects of your design and see how users will interact with it. You can also use prototypes to show potential customers what your product or design looks like.

Once you have a good prototype, it’s time to build your final product. You can use materials close to the final product—like plastic instead of wood—to save money and time. And because prototypes are used for testing, they should be easy to repair if something goes wrong.

Leading Rapid Prototyping Service Supplier

KAIAO is a professional technical enterprise providing customers with new product design stage verification, trial production, and low-volume production of your parts. Our services include rapid prototyping, CNC machining, reaction injection molding, low-volume manufacturing, vacuum casting, and sheet metal fabrication services. Our sales and engineering services are available whenever you need us.